Meet the calibration function of your furnace.

There is an offset/calibration setting in the settings section of all ovens. From time to time, the temperature you see on the panel of your oven may start to look different from the actual temperature inside the oven, due to reasons such as the aging of the thermocouple or the touch of the fired work to the thermocouple.

In such cases, we notice most junior technicians try to balance the firing temperature of the program they use by changing the firing temperature a few degrees up or down, or by changing the firing times, as a practical but faulty solution.

This method can provide a successful result for the currently used program, but since all the programs in the furnace are affected by the calibration shift, all of them require special intervention. the programs start to drift away of firing curve given by the powder producers.

To avoid this confusion, please train your technicians to always stick to the official firing curves and if your job is under or over fired, change the offset/calibration parameter for adjusting, do not edit the program.

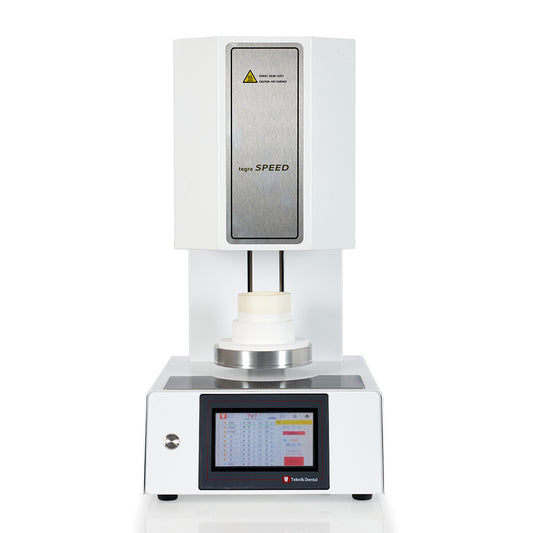

Access to calibration setting for PID controlled legacy devices

- tegra MP1500

- tegra MP1600

- tegra MP1500 Speed