Fusion Ceram produces zirconium blocks that are used by many of our customers and that we use frequently in our tests, with very high quality results. Besides its quality appearance, its main feature is its durability.

The main factors you need to pay attention to in order to get maximum efficiency from Fusion Ceram blocks;

Arrangement: Spread the crowns in the crucible by arranging them upside down so that they do not interfere with the movement of the edges during the shrinkage during sintering.

Slow Heating: When sintering your blocks, limit the temperature increase to a maximum of 5°C/min.

Maximum temperature: 1500 °C. For single or double crowns, it is usually sufficient to wait 2 hours at this temperature.

As the number of members increases, you should reduce the heating rate and extend the waiting time at 1500°C, but never exceed 1500°C. At higher temperatures, your blocks begin to lose their strength and become brittle.

Don't forget the oven cleaning, don't forget to clean your oven every 10 cycles, 100 hours or once a week using plain plain white, pure, uncolored, blank, broken block residues . The cleaning oven increases the resistance life and ensures that your work always comes out with a constant quality. It is also recommended to calibrate the oven (offset adjustment) at least once every 6 months.

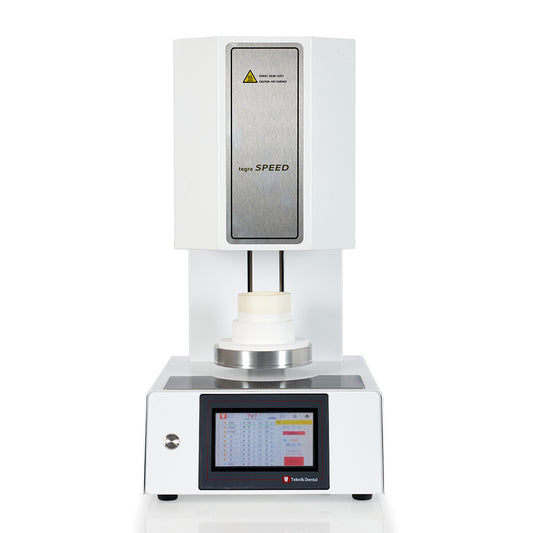

Manufacturer approved sample Programs for Fusion Ceram - Tegra ovens:

One Crown

| Target Temperature | Heating Rate | At target temperature standby time |

| 300°C | 10°C /min | 1 min |

| 1500°C | 5 °C /min | 120 min |

| 800°C | 5 °C /min | 120 min |

The last line parameter of Tegra sinter furnaces is the lift opening degree. You can leave the steps you do not use empty ( 0 °C ) .

For more information please visit fusionceram.com .