Introduction

In the previous blog post, we explained the natural origin of zircon and how it is transformed into zirconium oxychloride, a purified liquid material. This liquid is the starting point for most zirconia used in dentistry. However, what happens after this stage plays a critical role in determining the quality of the final zirconia disc.

At this stage, manufacturers make a series of important decisions. These decisions directly affect the final properties of the material, such as its strength, translucency, and how it behaves during processing. In this article, we explain the steps that turn zirconium oxychloride into a zirconia disc.

Step 1: Starting with Zirconium Oxychloride

Zirconium oxychloride is a water-based solution created by dissolving zircon sand through an acid purification process. It is the base liquid that all manufacturers use to create zirconia.

Step 2: Adding Yttria as a Stabilizing Agent

To make zirconia suitable for dental use, yttria (yttrium oxide) is added. This stabilizing agent helps maintain the material in the correct crystal structure.

There are two main methods of adding yttria:

-

Adding as a chloride in solution

-

Some companies dissolve yttria chloride directly into the zirconium oxychloride solution.

-

This results in a homogeneous, yttria-stabilized zirconia compound as the material precipitates.

-

-

Adding as an oxide powder later

-

Other manufacturers add yttria oxide powder after zirconia powder is created.

-

This method may be less efficient, depending on the application.

-

The timing and method of adding yttria strongly influence the final material properties.

Step 3: Controlling Particle Size in the Solution

Even before the material is solidified, manufacturers can control the size of the zirconia particles in the liquid. They do this using a process similar to milling.

-

Smaller particles can improve certain characteristics like translucency.

-

Larger particles may result in different optical and mechanical properties.

Controlling particle size is one of the most important variables in zirconia processing.

Step 4: Transforming the Liquid into a Solid Disc

Once yttria-stabilized zirconia is in liquid suspension form, manufacturers convert it into a solid disc. There are different fabrication methods:

-

Casting

-

Some manufacturers pour the liquid into molds to directly form a disc.

-

-

Spray Drying for Pressing

-

Other manufacturers add an acrylic binder to the liquid.

-

The mixture is passed through a hot air stream in a process called spray drying.

-

The water evaporates, leaving behind dry, acrylic-coated zirconia particles.

-

Spray drying is efficient and widely used when preparing zirconia for pressing.

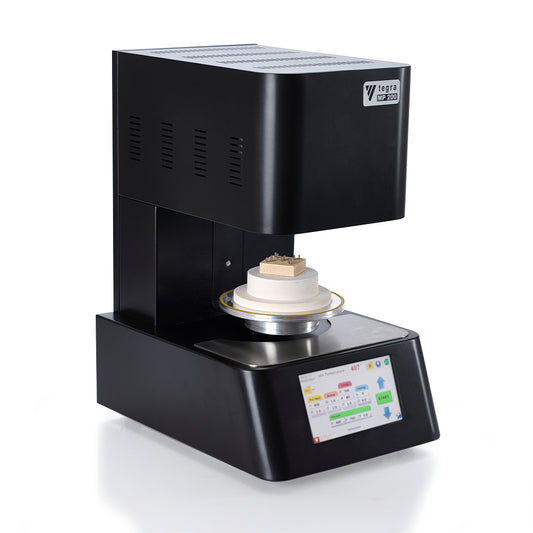

Step 5: Pressing the Zirconia Powder into Disc Form

The dry zirconia powder is pressed into a solid disc. There are two main pressing methods:

-

Hydraulic Pressing

-

A machine applies pressure from one direction to create the disc shape.

-

-

Isostatic Pressing

-

The disc is placed into a chamber where pressure is applied from all directions equally.

-

This ensures the disc has uniform density, which is important for consistent shrinkage during sintering.

-

Uniform density helps ensure accurate fitting for dental restorations.

Step 6: Shrinkage and Dimensional Accuracy

Even the method used to form the disc can affect how much it shrinks during sintering. Some manufacturers observe variations from disc to disc, especially when using pressing methods.

To reduce fit problems in complex restorations, such as long-span bridges, some manufacturers measure the shrinkage rate for each individual disc. This is more accurate than assigning an average value to a whole production batch.

Conclusion

The process of turning purified zirconium oxychloride into a finished dental zirconia disc involves many steps. These include how yttria is added, how particle size is controlled, and how the material is dried and pressed. Each of these choices impacts the final product’s translucency, strength, and accuracy during sintering.

Understanding these steps helps explain why not all dental zirconia materials are the same. The way a zirconia disc is made can significantly affect how it performs in your lab and in the patient’s mouth.