The regeneration of SiO2 (silicon dioxide) is typically most effective within a specific temperature range. Thermodynamically, the best temperature range for SiO2 regeneration is generally between 1000°C and 1300°C.

At temperatures below 1000°C, the regeneration of SiO2 is limited due to slower reaction rates. The oxidation of silicon (Si) to form SiO2 is a relatively slow process at lower temperatures. Additionally, the diffusion of oxygen (O2) through the SiO2 layer to react with underlying silicon is less efficient at lower temperatures. Therefore, the regeneration of SiO2 at temperatures below 1000°C may require longer exposure times or higher oxygen concentrations, making it less thermodynamically favorable.

On the other hand, at temperatures above 1100°C, the SiO2 layer can become less stable and prone to degradation. High temperatures can lead to the formation of volatile silicon oxide species, such as SiO and SiO2(g), which can escape from the SiO2 layer. This loss of silicon oxide species can result in a thinner or disrupted SiO2 layer, reducing its protective properties. Therefore, regeneration at excessively high temperatures may be thermodynamically less favorable as the SiO2 layer may not maintain its integrity.

The temperature range of 1000°C to 1300°C strikes a balance between efficient oxidation kinetics and maintaining the stability of the SiO2 layer. Within this range, the oxidation reaction between Si and O2 occurs at a reasonable rate, allowing for effective regeneration of SiO2. Moreover, the SiO2 layer remains stable and provides adequate protection against further oxidation at these temperatures.

Hold Time: The hold time at the regeneration temperature can vary but is generally in the range of 1 to 4 hours. This duration allows for sufficient diffusion and oxidation processes to occur, leading to the formation of a robust silica layer.

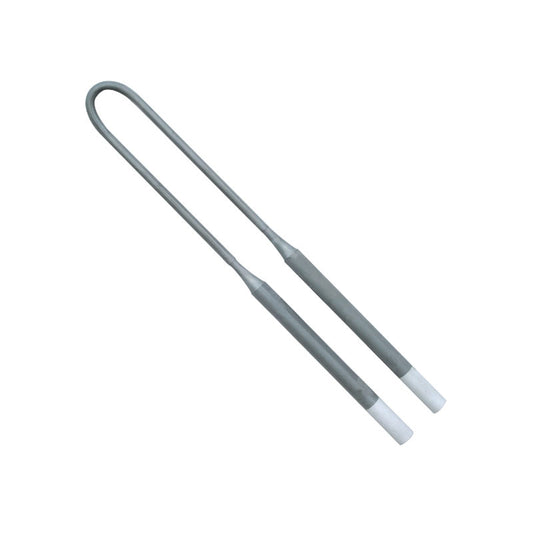

Heat Rate: The heat rate refers to the speed at which the temperature is increased during the regeneration process. It is crucial to ensure a controlled heat rate to prevent thermal shock and damage to the elements. A typical heat rate for MoSi2 elements is around 10-20°C/min. This gradual increase in temperature helps in achieving uniform heating and minimizes the risk of cracking.

Procedure

- Preheating: Start by preheating the chamber and the elements to a lower temperature, such as 300°C, to eliminate any moisture or contaminants present on the surface.

- Heating Stage: Increase the temperature gradually with a heat rate of around 10-20°C/min until you reach the desired regeneration temperature, 1300°C. This gradual heating ensures even temperature distribution and reduces the risk of thermal stress.

- Hold at Regeneration Temperature: Once the desired temperature is reached, maintain the chamber at this temperature for a recommended hold time of 1-4 hours. This duration allows for the necessary diffusion and oxidation processes to occur, resulting in the formation of a protective silica layer.

- Cooling: After the hold time, gradually cool down the chamber and the elements to room temperature. Avoid rapid cooling to prevent thermal shock and potential damage to the elements.

Phase Transitions: MoSi2 undergoes phase transitions at elevated temperatures. At temperatures below 1000°C, MoSi2 is in the "ordered" or "tetragonal" phase, which has a lower oxidation resistance. However, at temperatures above 1000°C, MoSi2 transforms into the "disordered" or "cubic" phase, which exhibits higher oxidation resistance and facilitates the formation of the protective silica layer.

Thermal Stress: The temperature 1300°C is chosen to minimize thermal stress on the MoSi2 elements during heating and cooling. Sudden and extreme temperature changes can induce thermal shock, leading to cracking or other damage to the elements. By using a controlled heat rate and operating within the recommended temperature range, the risk of thermal stress is reduced.

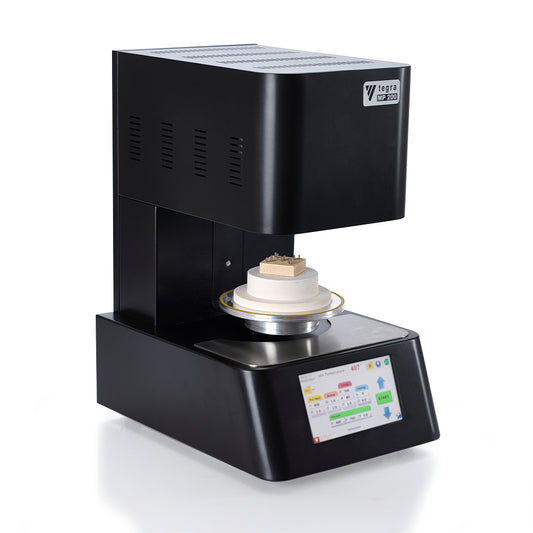

tegra MP1500 series MoSi2 silica layer regeneration program

| Step | Heat(C) | Rate(C/min) | Hold(min) |

| 1 |

300

|

10 | 0 |

| 2 | 1300 |

20 | 180 |

| Last |

300 | 0 | 30 |