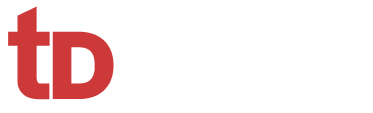

Our roots come from Dentistry artisanship with great influence on the local dental industry and Dental Furnaces are our only focus nearing 40 years.

As Teknik Dental, we have always prioritized the satisfaction of our customers in the steps to success we have taken so far. Operating under the framework of "Teknik Dental Values" worldwide, we keep our promises. Thanks to our innovation-focused R&D and production approach, we regularly optimize our product and service portfolio. Since our establishment, we have gone beyond borders in the dental industry with the products we have introduced, and we are always focused on creating better solutions. As a result, we shape the future in the industry.

Our roots come from dental restoration artisanship. We speak the same language as our customers who use Teknik Dental products and understand their needs.

We strive to ensure that our products and services are always of top-notch quality. We provide industry consulting, support, and spare parts services whenever our customers need them. Through our innovative products and services developed through R&D activities, we offer our customers a competitive advantage at market prices.