Murat Parlar, a dental technician who graduated and worked in Germany established Teknik Dental in 1984 with the goal of creating "solutions that create value" for the dental technology sector. With its unwavering service approach that puts a premium on quality and precision, Teknik Dental has led the way in the industry by focusing on the expertise of dedicated experts.

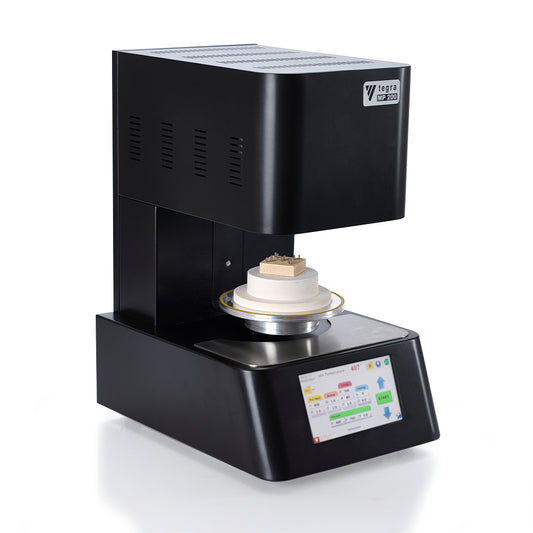

The company used a variety of analytical techniques to determine the market's needs, and then it started developing ground-breaking products by fusing beautiful design with great performance. In Turkey, Teknik Dental has doubled its market share over the past 5 years, earning the distinction producing the most popular dental porcelain and sintering furnace in Turkey.

Teknik Dental currently provides value-added solutions along with its services in 10 nations, primarily in Africa, MENA and Europe. As Teknik Dental, we uphold the original dream that was set years ago and work assiduously to take deliberate measures in the direction of success. We stay one step ahead of the dentistry industry while realizing our ideas thanks to our creative team and technologies created for dental technicians, dentists, and labs.

Ali Parlar, the son of Murat Parlar and a chemist and software specialist, has worked periodically both at Teknik Dental and in the international software industry. He has been a pioneer in the development of furnace software and took over the company management in January 2023.

As we move forward in our quest to establish ourselves as a recognized global brand, our aim is to make sure that our customers always feel the same level of enthusiasm.

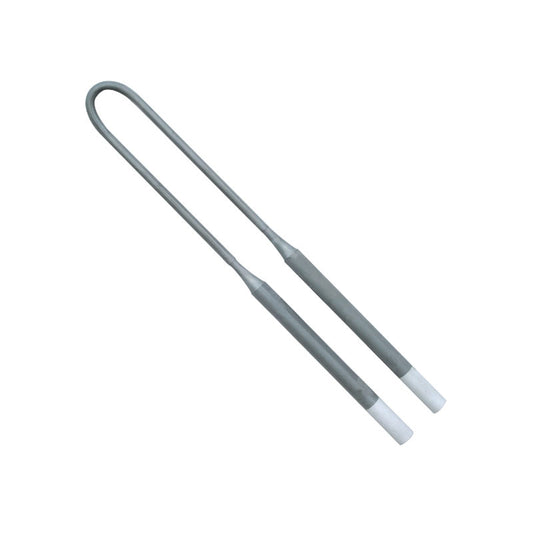

Our production area includes the Tegra porcelain furnace, which has been used for many years in the largest dental laboratories, as well as the Tegra zirconia sintering furnace. We also produce implant products, precision holders, and devices such as the fusing machines and parallelometers used in the assembly of holders.