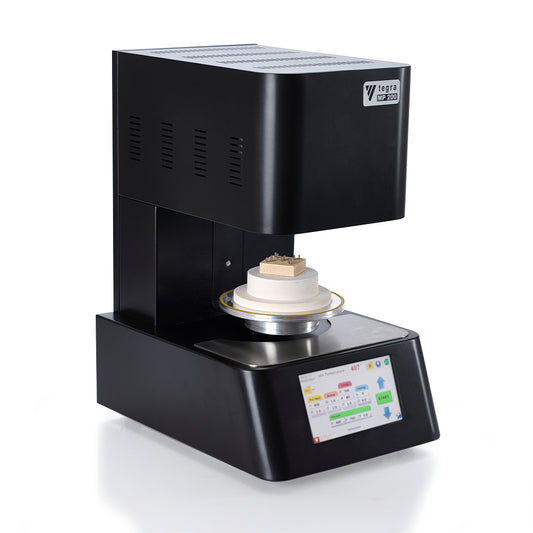

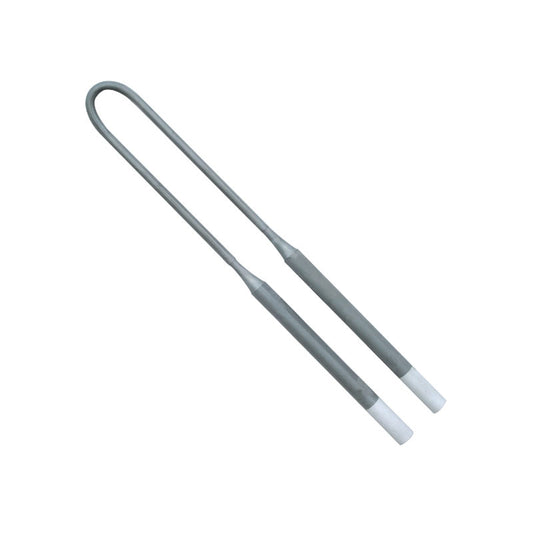

Teknik Dental is dedicated to providing our customers with high-quality goods and services. Our skilled workforce and entire quality management system ensure that our high quality standards are maintained throughout the manufacturing process.

We believe in standardizing our quality at all stages to ensure that every user receives the same high-quality product.

We at Teknik Dental are committed to making the world a better place via our efforts. We never compromise our quality principles in our customer interactions, pre- and post-sales processes, or activities.

To maintain a faultless workflow, we focus on inspection at all quality control stages, meticulously checking machine components and subsystems from procurement to shipment.