If you're starting a dental laboratory, congratulations on taking this exciting step! However, to ensure that your lab is successful, you need the right equipment, including furnaces. Furnaces are critical to the fabrication of dental restorations, and you'll need to invest in high-quality porcelain and sintering furnaces to achieve consistent, high-quality results.

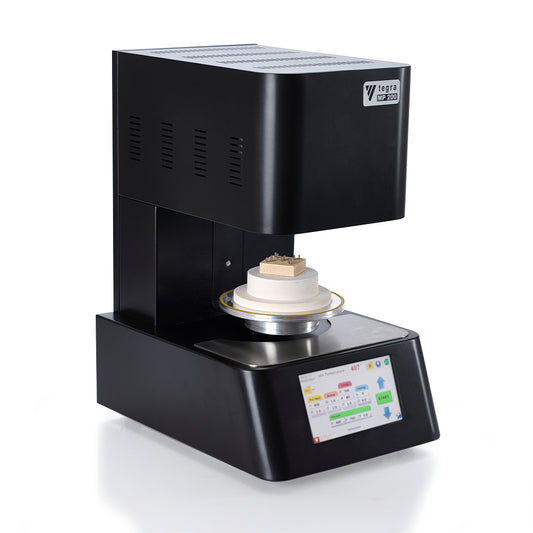

At Teknik Dental, we understand the importance of reliable and heavy duty furnaces in a dental lab. That's why we offer a range of porcelain and sintering furnaces specifically designed to meet the needs of dental technicians and lab owners. Our furnaces are manufactured using the latest technologies to ensure you get accurate and consistent results every time.

Furnaces are critical for your dental restorations, such as crowns and bridges, are made from materials like porcelain and zirconia. These materials are fired in furnaces at high temperatures to achieve their final shape and strength. This firing process is crucial to the success of the restoration, as it determines the strength, color and translucency of the final product.

As a dental technician or lab owner, you may be tempted to buy cheaper kilns to save money. However, this can be an expensive mistake. Low-quality furnaces can produce inconsistent firing results, resulting in weaker and less attractive restorations. This can lead to patient dissatisfaction, increased rework and a bad reputation for your laboratory. Investing in high-quality ceramic and sintering furnaces ensures that your dental lab consistently produces high-quality restorations that meet your patients' needs.

Our furnaces are designed to deliver precise, repeatable results every time. This saves you time and money while maintaining the highest quality standards. When choosing a porcelain or sintering furnace for your dental lab, it's important to consider your individual needs and requirements.

Teknik Dental offers a range of furnaces designed to meet the needs of different labs, from small start-ups to large, high-volume operations. Our porcelain furnaces are designed to provide excellent firing results for the full range of market of powder manufacturers.

tegra furnaces are ideal for sintering zirconia, providing precise and repeatable results. By investing in high-quality porcelain and sintering furnaces, you can ensure that your lab consistently produces high-quality restorations that meet your patients' needs. Contact us today to learn more about our porcelain and sintering furnaces and how they can take your dental lab to the next level.