As a proprietor or technician of a dental laboratory, you are aware of the need of preserving the quality of your supplies and machinery in order to provide restorations of the highest caliber.

The cleaning of the zirconia furnace is one area in the lab that is frequently disregarded.

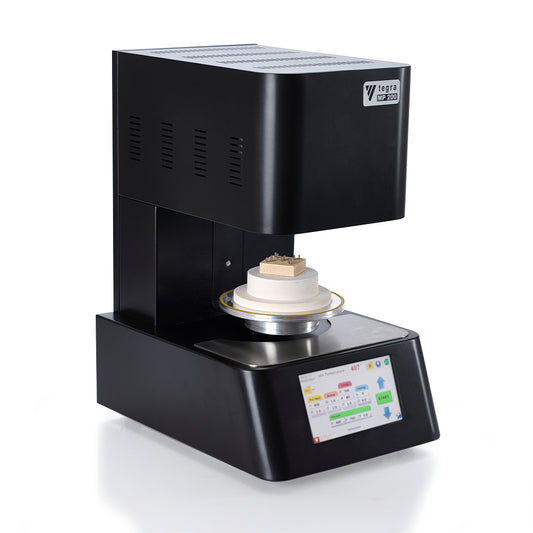

The furnace is a crucial piece of machinery that needs to be cleaned frequently to keep it operating correctly and delivering precise results. In this article, we'll go through a straightforward but efficient technique for cleaning your zirconia furnace with the remaining zirconia blanks.

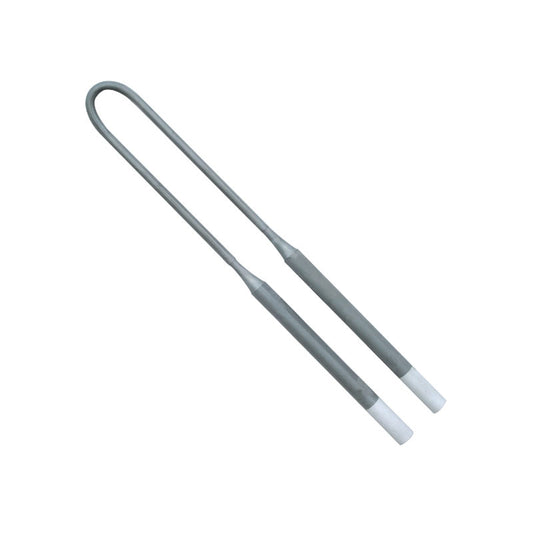

After milling, don't discard the leftover zirconia blanks. The components that have already been treated are ideal for cleaning your furnace. There is always some residual material while milling a zirconia repair that cannot be used for the finished product. You can use these parts to clean your furnace rather than discarding them. Due to its extreme hardness and abrasiveness, zirconia is the ideal material for cleaning out any pollutants that may have accumulated inside the furnace.

A cleaning program needs to be run on the zirconia furnaces after ten firings or 100 hours, whichever comes first. Even if you don't use your furnace frequently, it still has to be cleaned routinely to avoid pollutants or oxide buildup. Failing to clean your furnace might lead to substandard repairs and a shorter equipment lifespan.

You can load the broken zirconia blanks onto the tray and fire them at 1550 degrees for 4 hours to clean your furnace using the leftover zirconia blanks. This procedure will aid in the absorption of impurities and enable the MoSi2 heaters to regenerate their shielding silica layer. All impurities will evaporate during the heating process, leaving a clean, fresh surface for your subsequent fire.

There are various benefits to using this cleaning technique on your zirconia furnace. The first benefit is that you may clean your furnace affordably by using waste materials that would otherwise be thrown away. Second, it's an eco-friendly approach that encourages sustainability and minimizes waste. Finally, it's a straightforward procedure that anyone in the lab can complete with little instruction.

There are further actions you may take to make sure your furnace is operating properly in addition to cleaning it using zirconia blanks. For instance, you should frequently examine the heating components and thermocouple to make sure they are functioning properly. To make sure that it is accurate and consistent, you should also keep an eye on the furnace's internal temperature.

Oxide will begin to build up after the furnace is cold. If the furnace has not been used for even 8 hours, this build up will form as yellow stains around the tray. We advise a 1 hour quick firing to remove these oxides before firing your original work.

MP1500 series sintering furnaces chamber and tray decontamination program

| Step | Heat(C) | Rate(C/min) | Hold(min) |

| 1 |

300

|

10 | 0 |

| 2 | 1530 | 25 | 240 |

| Last |

600 | 25 | 30 |