Porcelain Furnace Maintenance: 7 Essential Tips for Reliable Performance

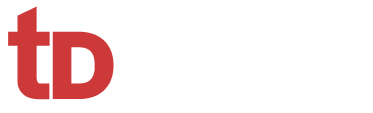

<p>Whether you're a dental technician or a practicing dentist, your porcelain furnace is one of the most critical tools in your workflow. Like any precision device, it performs best when it's treated well. With just a few simple routines, you can keep your TEGRA furnace (or any porcelain furnace) running like new — minimizing downtime and ensuring consistent, high-quality results.</p>

<h2>1. 🔍 Daily Visual Inspection</h2>

<p>Before powering on, take a quick look:</p>

<ul>

<li>Check the <strong>heating chamber</strong> for dust, ceramic particles, or glaze residue.</li>

<li>Make sure the <strong>furnace tray/platform</strong> is sitting flat and not cracked.</li>

<li>Look for discoloration, cracks, or contamination in the insulation.</li>

</ul>

<blockquote>

Tip: A small flashlight can help spot hidden buildup around the edges.

</blockquote>

<h2>2. 🪝 Clean the Chamber Weekly</h2>

<p>Even if everything looks fine, residue from repeated firings can build up and affect the temperature curve.</p>

<ul>

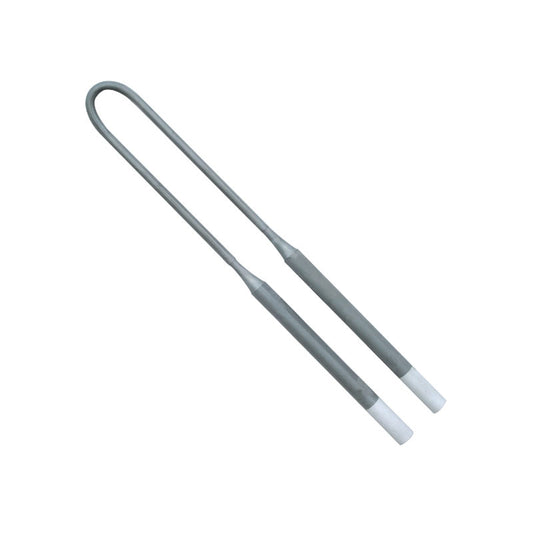

<li>Use a <strong>soft brush</strong> (never metal) to gently remove debris.</li>

<li>Do not use alcohol or water inside the hot zone.</li>

<li>Wipe external surfaces with a microfiber cloth.</li>

</ul>

<h2>3. 💾 Use Clean, Dry Materials</h2>

<p>Contaminants don’t always come from inside. Dirty or wet ceramic components can cause:</p>

<ul>

<li>Unwanted fumes or gas buildup</li>

<li>Particle burns on restorations</li>

<li>Sensor calibration drift</li>

</ul>

<blockquote>

Golden Rule: Always load <strong>completely dry</strong> crowns or bridges.

</blockquote>

<h2>4. 🌡️ Calibrate Monthly</h2>

<p>Factory calibration is reliable, but over time:</p>

<ul>

<li>Sensor drift may occur</li>

<li>Voltage fluctuation may affect compensation</li>

</ul>

<p>Run a known firing program or contact support for remote help.</p>

<h2>5. ⚡ Watch Your Power Supply</h2>

<p>Voltage spikes and grounding issues are furnace killers. Ensure:</p>

<ul>

<li>Proper grounding of the outlet</li>

<li>Dedicated circuit without compressors or ovens</li>

<li>Surge protection is in place</li>

</ul>

<h2>6. Avoid Overloading</h2>

<p>Overloading affects heat distribution and can stress components. Stick to recommended capacity and spread items evenly.</p>

<h2>7. 📞 Know When to Call</h2>

<p>If you notice:</p>

<ul>

<li>Unusual smells</li>

<li>Extended heating times</li>

<li>Cracks in the chamber</li>

<li>Irregular sounds</li>

</ul>

<p>Contact <strong>TEGRA support</strong>. Early diagnosis is key.</p>

<h2>✅ Final Words</h2>

<p>A porcelain furnace is not just a heating tool — it's an investment in precision. With just a few minutes of care per week, you can dramatically extend its lifespan and avoid costly downtimes.</p>

<p>At TEGRA, we build our furnaces to be reliable and service-friendly — but great performance starts with great habits.</p>

<p><strong>Need help with maintenance or calibration?</strong><br>

Contact our support team — we’ll walk you through it in under 10 minutes.</p>