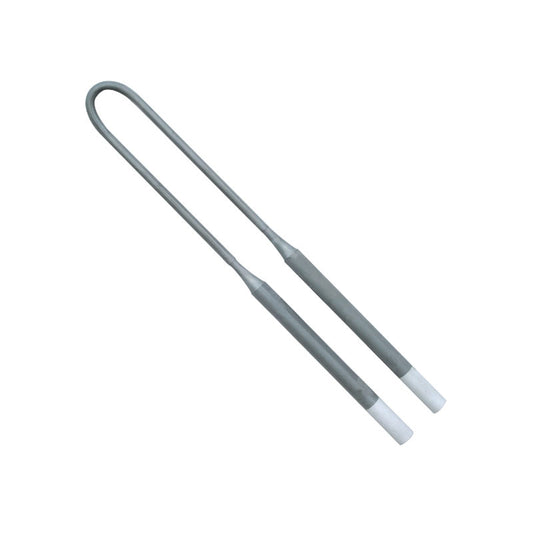

Silicon carbide (SiC) heating elements play a critical role in industrial applications requiring high temperatures and high power. Their unique properties make them a superior choice over many traditional heating elements.

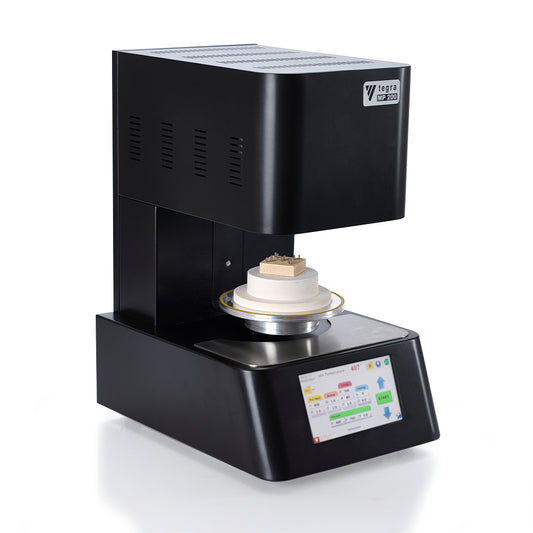

One of the most significant advantages of SiC elements is their ability to withstand high temperatures. Exceeding the limits of metallic elements, SiC can operate at temperatures up to 1600°C. This makes them ideal for processes requiring high temperatures, such as ceramics, glass, and metal processing. SiC elements can also handle high watt loads. This allows them to generate more heat in a smaller area, resulting in more compact and efficient furnaces.

The self-supporting nature of SiC elements is also a significant benefit. This means they can be used without the need for additional support structures within the furnace.

Additionally, SiC elements are known to have less of a discoloring effect on zirconia compared to MoSi2 heaters. This makes SiC elements a preferred choice in applications where the color of zirconia needs to be preserved. This is especially valuable when working with difficult zirconia blocks that are highly intolerant.

However, SiC elements also have some disadvantages. For example, their electrical resistance increases over time. This phenomenon, known as "aging," requires more maintenance, such as transformer tap changing and group replacement of elements. Additionally, SiC elements are more expensive than metallic elements and require specialized power control equipment.